Arduino Portenta Machine Control

AED 1,650.00

Available on backorder

Available on backorder

| Stock | Location | Shipping Method | ETA | Cost |

| Available | Abu Dhabi | Self Pickup | Wednesday-Saturday: Will be available for pick up on Tuesday Sunday-Tuesday: Will be available for pickup on Thursday | Free |

|---|---|---|---|---|

| Available | Dubai | Self Pickup | 1-2 Days | Free |

| Available | UAE Remote Areas | Delivery | 4-5 days | 22 AED / Free Above 50 AED |

| Available | UAE Urban Areas | Delivery | 2-3 Days | 22 AED / Free Above 50 AED |

| Available | International | Delivery | 4-7 days | 180 AED | 49 $ |

| Pre-Order | General | 2-3 weeks |

Payment Methods:

Specifications:

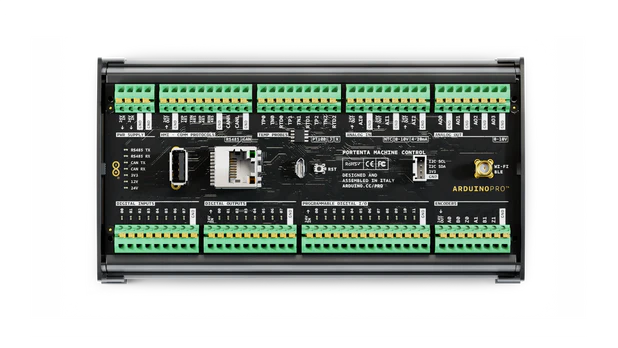

The Arduino Portenta Machine Control is designed as a fully-centralized, low-power industrial control unit, suitable for driving equipment and machinery, and tailored for applications in the Industry 4.0 and IIoT (Industrial Internet of Things) spaces. It’s built around the robust Portenta H7 microcontroller, offering advanced features and connectivity to cater to modern industrial automation needs.

- Microcontroller Core: Utilizes the Portenta H7 Core.

- Processor: Powered by an STM32H747XI dual-core (Cortex-M7 running at 480 MHz + Cortex-M4 at 240 MHz).

- Memory: Equipped with 8MB of SDRAM and 16MB of onboard Flash memory for ample storage and efficient processing.

- Connectivity: Offers wireless communication via BLE and Wi-Fi, along with Ethernet and a USB programming port for versatile network connections.

- I/O Capabilities: Features isolated digital I/O, 4-20mA compatible analog I/O, 3 configurable temperature channels (supporting PT100/J/K temperature probes), and a dedicated I2C connector. The machine control also includes 12 programmable digital I/Os operating at 24 V logic.

- Power Supply: Operates on a 24V DC power source, with dimensions making it compact for industrial applications (90x170x50 mm) and a weight of 186g.

- Operating Temperature: Designed to function reliably within industrial temperature ranges from -40° C to +85° C.

- Communication Protocols: Supports CAN-BUS and programmable serial ports (232, 422, 485), catering to a variety of industrial communication needs.

This device is engineered to enhance the intelligence of industrial products, shortening time-to-market, and offering the flexibility needed for the AI and IoT revolution in manufacturing and production processes. It’s particularly aimed at enabling the collection of real-time data from factory floors and supporting remote control of equipment, even from the cloud, making it a versatile choice for predictive maintenance and AI use cases.

Learning Resources:

Portenta Machine Control Documentation

Applications and Projects:

The Arduino Portenta Machine Control is a versatile platform designed for industrial applications, making it ideal for a wide range of use cases in Industry 4.0, automation, and edge computing. Here are some of the potential applications and project examples where this device can be particularly effective:

- Industrial Automation: The Portenta Machine Control can serve as the heart of an industrial automation system, controlling machinery and processes on the factory floor. Its robust design and connectivity options make it suitable for tasks such as managing conveyor belts, robotic arms, and other automated production line components.

- Predictive Maintenance: Thanks to its capability to process and analyze data in real-time, the Portenta Machine Control can be used for predictive maintenance of industrial equipment. By monitoring machine health through vibration analysis, temperature readings, and other sensors, it can predict equipment failures before they occur, minimizing downtime and maintenance costs.

- Remote Monitoring and Control: The device’s networking capabilities, including Ethernet, Wi-Fi, and Bluetooth LE, allow for the remote monitoring and control of industrial equipment. This is useful in scenarios where machinery needs to be controlled or monitored from a distance, enhancing operational efficiency and safety.

- Data Collection and Analysis: In the context of the Industrial Internet of Things (IIoT), the Portenta Machine Control can act as a data hub, collecting data from various sensors and devices on the factory floor. This data can then be analyzed to optimize production processes, improve product quality, and reduce waste.

- Human-Machine Interfaces (HMIs): The device can also be used to develop advanced HMI systems for industrial applications. This includes the creation of control panels, touch screens, and dashboards that provide operators with real-time information about the status and performance of machinery and processes.

- Custom Industrial Solutions: Its modular design and configurable I/O pins make the Portenta Machine Control highly adaptable for custom solutions. Whether it’s for controlling a batch freezer, a cartoning machine, or integrating with existing industrial systems, the device offers the flexibility to meet specific project requirements.

Product Attributes :

Specification

| Part Number |

AKX00032 |

|---|---|

| Unit Of Measure |

Each |

| Brand |

Arduino |

Product Reviews:

You must be logged in to post a review.

Reviews

There are no reviews yet.