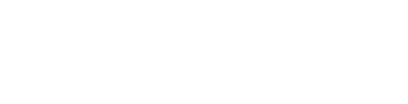

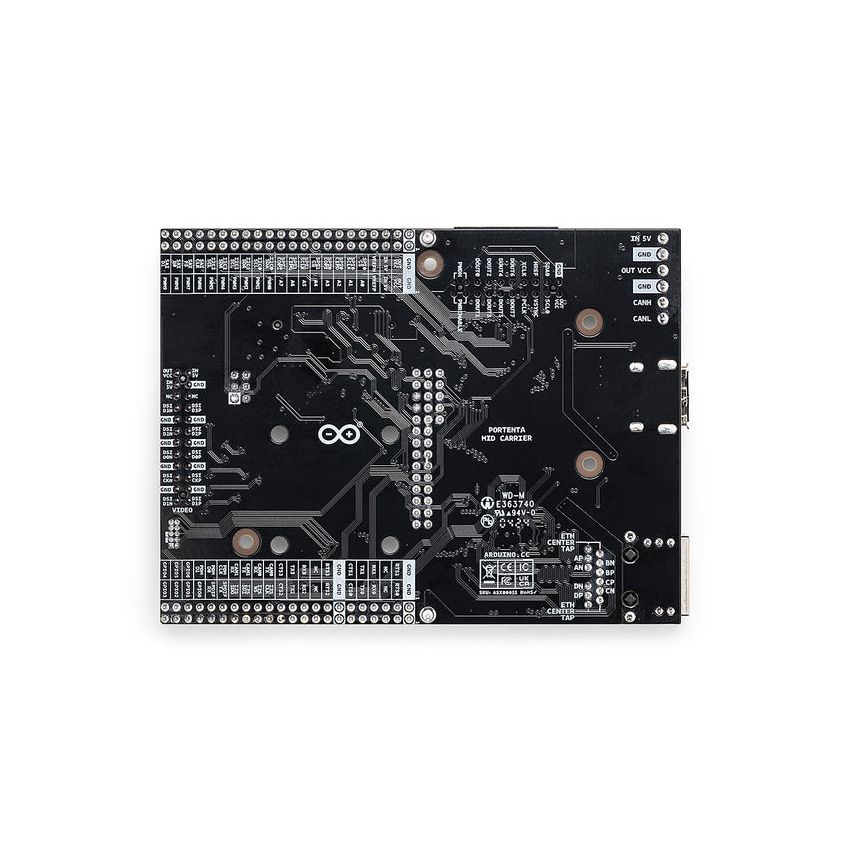

The Portenta Mid Carrier is designed to extend the capabilities of the Portenta family of development boards by Arduino, such as the Portenta H7 and X8. Here are the detailed technical specifications for the Portenta Mid Carrier:

Connectors:

USB-A female connector

Gigabit Ethernet connector (RJ45)

Two CAN bus interfaces (one with onboard transceiver and one without)

Mini PCIe (mPCIe) connector

MIPI Camera connector

Arducam Camera connector

MicroSD card slot

RTC LiPo battery slot

Giga Display Shield connector

Interfaces: Includes support for CAN, SAI, I2S, PDM, GPIO, SPI, I2C, PWM, and ANALOG I/Os.

Power Options:

Power can be supplied through a USB-C connection on the Portenta board, a 5V supply via the headers, or from an onboard screw terminal block.

Operating Temperatures: The device operates within a temperature range of -40 °C to 85 °C (-40 °F to 185 °F).

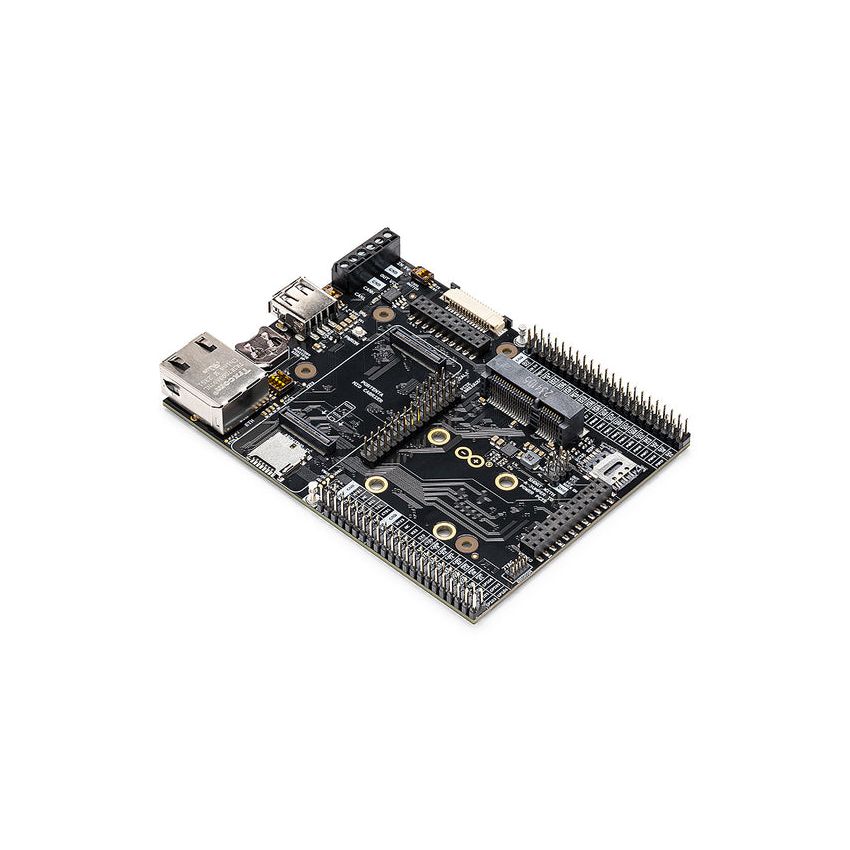

Dimensions: The carrier measures 114 mm x 86.5 mm (4.49 in x 3.41 in).

Debugging Features: Includes onboard JTAG pins for debugging.

This carrier board is particularly suitable for rapid prototyping and development of industrial, IoT, and machine vision applications due to its robust connectivity and interface options

Learning Material

Applications

The Portenta Mid Carrier is a versatile expansion board that offers a broad range of application possibilities, particularly suited for high-performance and industrial projects. Here are some of the key applications and project examples involving the Portenta Mid Carrier:

Machine Vision Prototyping: The Portenta Mid Carrier, especially when used with the Portenta H7 or X8 boards, facilitates the development of advanced machine vision systems. It supports MIPI and Arducam® camera interfaces, which are ideal for applications like object detection, recognition, and defect identification in industrial settings.

Industrial Automation: Leveraging its multiple connectivity options such as CAN bus interfaces and Ethernet, the Mid Carrier is well-suited for industrial automation projects. It can handle robust data transmission needs, making it fit for factory automation, robotics, and building automation systems.

Remote Monitoring and Fleet Management: With the mini PCIe connector, the Mid Carrier can be equipped with cellular modules for remote communication. This feature is particularly useful for developing solutions in smart cities, smart agriculture, and fleet management, where long-range and reliable connectivity is crucial.

Data Logging: Thanks to its onboard microSD card slot, the Mid Carrier can be used for extensive data logging applications. This is beneficial in environmental monitoring, where capturing and analyzing large datasets over time is necessary.

Prototyping for Connected Devices: The board provides seamless integration with other hardware and is designed for frictionless prototyping. This makes it an excellent tool for developers looking to quickly test and iterate on designs involving a wide range of sensors and peripherals.